Réalta Develop Demo of LLM integrated with industrial data

Introduction

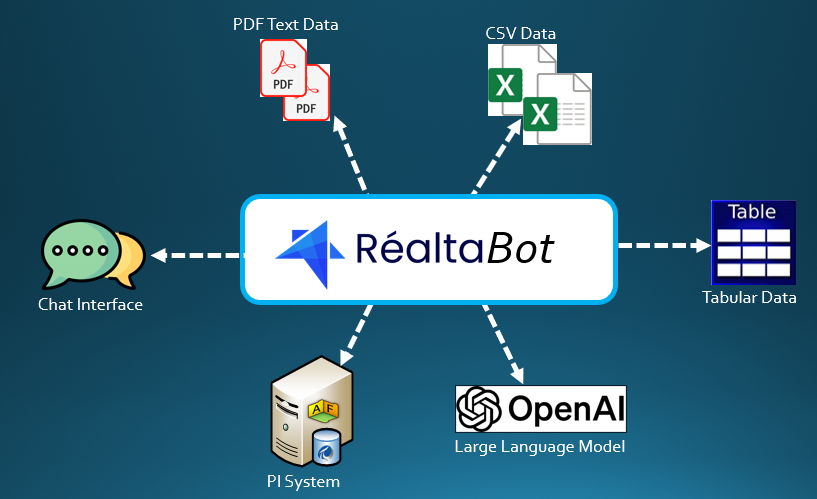

In the ever-evolving landscape of technology, the intersection of artificial intelligence and manufacturing processes has given birth to groundbreaking innovations. Here at Réalta Technologies we want to be at the cutting edge of technology and push the boundaries of AI in manufacturing. With this in mind, we created RéaltaBot! With this project we succeeded in showcasing the potential of generative AI to transforming the manufacturing sector. In this blog post, we will delve into the world of RéaltaBot, exploring how it harnesses the power of generative AI to interact with live manufacturing data from a PI system, and revolutionizes the way we perceive and operate within the manufacturing industry.

Understanding RéaltaBot

Developed as a demo chatbot application, RéaltaBot utilizes advanced generative AI algorithms to communicate with various data sources, most notably live manufacturing data from a PI system. The PI system, a renowned industrial data platform, provides real-time insights into manufacturing operations, making it an invaluable source of information.

The Power of Generative AI

At the heart of RéaltaBot lies generative AI, a subset of artificial intelligence that enables machines to generate new, unique content based on patterns and data inputs. Leveraging deep learning techniques, generative AI empowers RéaltaBot to process complex manufacturing data, interpret patterns, and respond intelligently to user queries. This capability opens doors to a myriad of possibilities within the manufacturing domain.

Transforming Manufacturing Operations

Real-time Insights: RéaltaBot’s ability to interact with live manufacturing data means that it can provide real-time insights into production processes. By analyzing this data, RéaltaBot assists manufacturers in identifying inefficiencies, predicting maintenance requirements, and optimizing production schedules, thereby enhancing overall operational efficiency.

Data-Driven Decision Making: Manufacturing decisions are often data-driven. RéaltaBot acts as a bridge between raw data and actionable insights. It processes vast amounts of data, identifies trends, and presents this information to decision-makers in a comprehensible manner. This empowers businesses to make informed decisions swiftly, ensuring a competitive edge in the market.

Predictive Maintenance: One of the critical aspects of manufacturing is machinery maintenance. RéaltaBot analyzes historical and live data to predict potential equipment failures. By anticipating maintenance needs, manufacturers can schedule repairs proactively, minimizing downtime and maximizing productivity.

The Future of Manufacturing

RéaltaBot exemplifies the symbiotic relationship between human ingenuity and artificial intelligence. As it continues to evolve, it paves the way for a future where manufacturing processes are not just efficient but also intelligent. With the integration of generative AI, live data analysis, and human expertise, RéaltaBot is poised to transform the manufacturing landscape, making it more agile, responsive, and capable of meeting the demands of an ever-changing market.

Conclusion

In the grand tapestry of technological advancements, RéaltaBot stands as a testament to the limitless possibilities of generative AI. By bridging the gap between raw data and meaningful insights, RéaltaBot not only enhances manufacturing efficiency but also augments human potential. As we look to the future, it is innovations like RéaltaBot that remind us of the extraordinary heights we can achieve when we combine human creativity with the power of artificial intelligence, leading us towards a future where manufacturing is not just about production but also about intelligent, data-driven decision-making.

Driving Sustainability in Manufacturing: How Réalta Technologies Empowers Facilities to Optimise Energy Use

Sustainability in manufacturing is critical to reducing environmental impact and operational costs. Learn how Réalta Technologies helps manufacturing facilities capture and analyse energy data to

Réalta Technologies Implements High-Availability PI System for BioPharma Site

Réalta Technologies improves a BioPharma site data collection, storage, analysis and visualisation by implementing a High-Availability PI System.

Réalta Technologies: Improving manufacturing productivity through certified SEEQ partnership

Réalta Technologies is now a certified SEEQ partner, enabling our engineers to offer top-tier data analytics solutions. Learn how this certification benefits our clients and